eMobility at Mercedes‑Benz Trucks

Ready for tomorrow today.

Welcome to change: the switch to eMobility is revolutionising an entire industry. Reduced emissions, lower operating costs, quiet and comfortable driving – battery-electric trucks are the future of transport. We are already setting the right course today to help shape it successfully. And help our customers to take advantage of the opportunities of the future.

eMobility – how did it all begin?

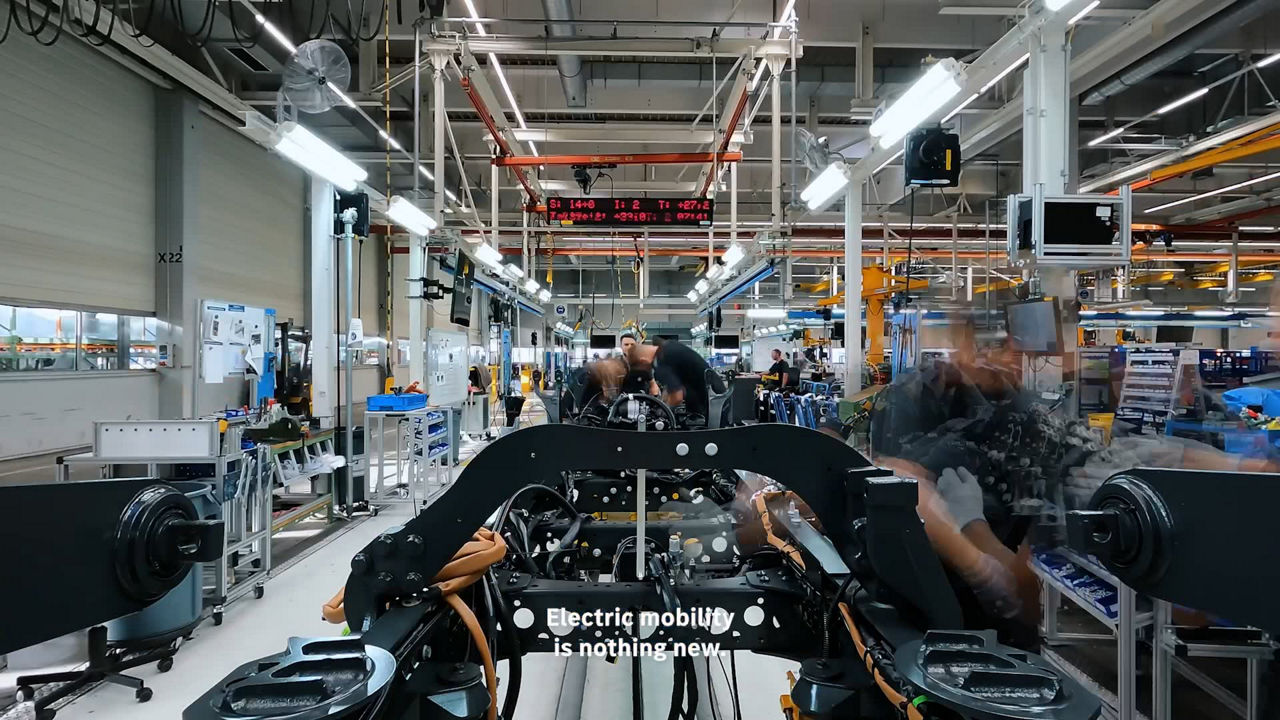

From research to production.

It all began as a research project on alternative drives and the opportunities of hydrogen and batteries. But what was theoretical laboratory work back then has now become a reality on the road: in 2016, we presented our first prototype of a battery-electric truck. In 2021, the eActros 300/400 followed, which proved successful in practice. In 2022, the eEconic, our electrified truck for urban use, was launched. In 2023, we took another important step towards battery-electric transport with the eActros 600.

In 2025, the eArocs 400 will impress in low-noise and locally CO2‑neutral use in urban construction haulage. The new eActros 400 also expands the eActros family and opens up a number of additional possibilities for CO2‑reduced delivery transport. It thus expands a vehicle portfolio in which you too will find a suitable solution for your path to a sustainable, electrified future.

What is our vision?

Steering into the future together.

Mercedes‑Benz Trucks customers like you make transport reliable, safe and efficient all over the world. Because of this, we are very aware of the key role we play in society – and of the responsibility that comes with it. After all, the demand for sustainable transport is growing rapidly. We have a clear ambition to play a leading role in the transformation of the industry. It was this pioneering spirit that drove us to invent the very first automobile and it is this pioneering spirit that inspires us to continue playing a leading role in the industry today.

Electrified

Season 1: Challenge accepted

The first season of the brand new Electrified series follows Logistik Schmitt, a company from Bietigheim, on its journey to eMobility. As a Mercedes‑Benz Trucks testing partner, the company faces new challenges every day, ranging from infrastructure and costs to driver scepticism. But Rainer Schmitt says: “Challenge accepted!” Can the company overcome the many hurdles and even get drivers excited about the new technology?

- Trailer: Challenge accepted

- Episode 1: Infrastructure

- Episode 2: Costs under control

- Episode 3: eActros? No, thanks?

- Episode 4: Customers are electrified

- Episode 5: High-voltage: the eActros 600 is coming

FAQs about eMobility

What moves you

Getting started with a new technology usually involves major challenges, a number of uncertainties and sometimes even prejudices. Here, our eMobility experts answer your most frequently asked questions.

“We want our customers to engage with the topic of charging infrastructure and we encourage them to consider all aspects at an early stage. Important topics are, for example, grid capacities and the duration of the necessary electricity planning and the final construction of the charging infrastructure.”

“Cold temperatures have a negative influence on the range of an eTruck. That’s why we carry out extensive tests, for example, in northern Finland, at temperatures down to minus 25 degrees Centigrade. We also have a battery management system that keeps the temperature of the battery at the right level throughout operation.1”

“We plan to make it possible to charge the batteries of the eActros 600 from 20% to 80% in about 30 minutes at a charging station with around one megawatt of energy.2”

“Just like our diesel trucks, our battery-electric trucks also meet the safety requirements. We also carry out crash tests with them, for example. We also have a battery safety concept that, for example, monitors the temperature of the battery throughout the entire operation of the truck. To further increase safety, our eTrucks naturally also have our comprehensive driver assistance systems, such as Active Brake Assist3.”

“You might think there’s an empty space, but that’s actually not the case. This is where our frontbox has been installed, where we have used the space efficiently to accommodate pumps, compressors and control units, for example.”

“They sound great. We have installed an audible vehicle warning system that generates artificial sound and makes the truck noticeable in its surroundings, especially at lower speeds.”

You may also be interested in:

Charged to change

Charging solutions for your business

In charge for a new era

Images and texts may include accessories and special equipment that do not form part of the standard delivery package. Images shown must be considered examples only and do not necessarily reflect the actual state of the original vehicles. The appearance of the original vehicles may differ from these images. Subject to changes without notice. Images and texts may also include models, support services, services and products that are not available in certain countries.

As an internationally operating company, equal opportunities, diversity, openness and respect are among the core beliefs of Daimler Truck AG. We show this in the way we think, act and communicate. All selected terms include all genders and identities as a matter of course.

1 The range has been determined internally under specific test conditions, after preconditioning with a 4x2 semitrailer tractor with a gross vehicle combination weight of 40 t, at an ambient temperature of 20°C in long-distance operation, and may deviate from the values determined in accordance with Regulation (EU) 2017/2400.

2 Based on internal simulations because a binding and uniform Megawatt Charging System (MCS) standard is currently still being developed.

3 Assistance systems can only support drivers. The driver is always fully responsible for driving the vehicle safely.